Strut Happens: What Works, What Doesn’t

Strut channel isn’t just framing—it’s infrastructure. It anchors conduit, cable tray, boxes, lighting, and mechanical systems across commercial, industrial, and institutional environments. But compatibility isn’t guaranteed. Profile depth, slot pattern, gauge, and finish all dictate what fits, what fails, and what holds up under load. With NEC 2026 now applying updated routing, protection, and separation requirements to limited energy systems, strut plays an even more critical role in supporting compliant installations.

1. What is strut channel and why is it used?

Strut channel is a standardized metal framing system used to support conduit, cable tray, mechanical piping, and equipment. It allows modular assembly using slotted or solid steel profiles, with pre-engineered fittings that eliminate welding or drilling. When strut is used to support limited energy systems under NEC 2026—such as PoE, communications cabling, or Class 2/3/4 circuits—routing and mechanical protection requirements in Articles 720–723 apply.

2. Where is strut channel typically used?

Strut is deployed in commercial, industrial, and institutional settings—supporting conduit, cable tray, HVAC piping, lighting, and equipment racks. It’s common in data centers, hospitals, schools, and utility plants. Outdoor use demands hot-dip galvanized or stainless finishes; food-grade zones require stainless with sealed fittings. When strut supports limited energy circuits, NEC 2026 requires compliant routing, separation, and mechanical protection.

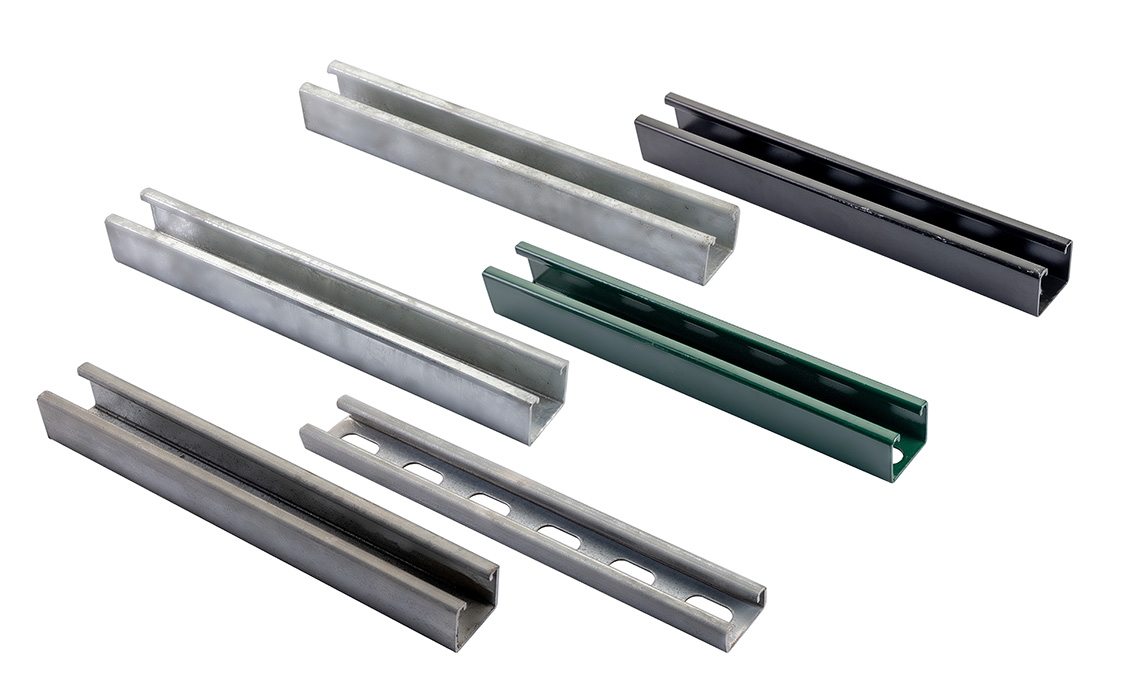

3. What are the standard strut sizes and profiles?

Common profiles include 1-5/8" x 1-5/8" (deep channel), 1-5/8" x 13/16" (shallow channel), and 1-1/2" x 3/4" (mini strut). Profiles may be solid, slotted, or punched. Depth and gauge affect load rating, compatibility, and fitting selection. When supporting limited energy cabling, ensure the profile and gauge provide adequate mechanical protection per NEC 2026.

4. What finishes are available—and when do they fail?

Typical finishes include pre-galvanized, hot-dip galvanized, powder-coated, and stainless steel. Pre-galvanized fails in outdoor or corrosive environments. Hot-dip is preferred for exterior use. Stainless is required in food-grade or chemical zones. Powder coating adds color but not corrosion resistance. When strut supports limited energy systems, finish selection must also consider environmental protection requirements for those circuits under NEC 2026.

5. What fittings work with strut channel?

Fittings include angle brackets, T-connectors, U-bolts, beam clamps, spring nuts, rod couplers, box brackets, tray supports, seismic braces, and grounding lugs. Compatibility depends on profile depth, slot pattern, gauge, and torque discipline. Always match fitting type to strut geometry and system load. When supporting limited energy circuits, ensure fittings provide proper mechanical protection and maintain required separation from higher‑voltage systems per NEC 2026.

6. What causes misalignment in strut assemblies?

Misalignment stems from mixing incompatible profiles, mismatched slot patterns, gauge variation across brands, improper fitting orientation, and under-torqued fasteners. Field failures often trace back to skipped anchoring, asymmetrical brackets, or assuming interchangeability. Always verify profile, finish, and hardware spec before install. NEC 2026 adds additional scrutiny when strut supports limited energy circuits, requiring proper routing, support, and mechanical protection.

7. How do you attach hardware and conduit to strut?

Strut supports a wide range of hardware—bridle rings, threaded rod, conduit, and boxes—using modular fittings and slot-compatible fasteners. When supporting limited energy circuits, NEC 2026 requires compliant routing, mechanical protection, and separation from higher‑voltage systems.

- Bridle rings: Use spring nuts, channel nuts, or adapter plates to seat bridle rings securely in the strut slot. Verify thread type and load rating. For cable separation, stagger rings by signal type and maintain vertical clearance. NEC 2026 requires proper mechanical protection and separation for limited energy circuits.

- Threaded rod: Attach using rod couplers, beam clamps, or strut inserts. Match thread size and torque to load requirements. Brace vertical runs as needed. When supporting limited energy systems, ensure rod assemblies maintain required separation from higher‑voltage pathways.

- Conduit: Secure with strut clamps, U-bolts, or cushion clamps sized to conduit OD. NEC support spacing applies—typically 10 feet for horizontal runs—following the updated limited energy routing and support requirements in NEC 2026 when applicable.

- Boxes: Mount using box brackets, offset plates, or custom strut assemblies. Ensure box depth matches strut profile and mounting hardware clears conduit entry. For limited energy systems, NEC 2026 requires proper mechanical protection and separation from higher‑voltage systems.

8. What’s the rule on conduit and cable tray support?

Strut must be sized for load and span. NEC and NEMA standards dictate spacing—typically 10 feet for conduit and 5 feet for cable tray. Use spring nuts or channel brackets rated for the load. Never rely on friction or undersized fasteners. When supporting limited energy circuits, NEC 2026 requires compliant routing, mechanical protection, and separation from higher‑voltage systems, especially in mixed‑voltage environments.

9. What causes strut failure in the field?

Top failure modes include overloading, corrosion, improper anchoring, and thermal expansion stress. Field audits often reveal missing bracing, unsupported spans, or incompatible materials. Always verify finish, gauge, and torque specs. When strut supports limited energy circuits, NEC 2026 adds requirements for mechanical protection, routing discipline, and separation, which must be followed to avoid compliance failures.

10. What are common installation errors to avoid?

Top errors include mixing incompatible profiles, under-torquing fittings, skipping anchoring, and overloading spans. Misaligned slots or mismatched hardware lead to stress fractures and field failures. Never assume interchangeability across brands. NEC 2026 adds additional requirements when strut supports limited energy circuits, including proper routing, mechanical protection, and separation from higher‑voltage systems.

11. Can strut be used for seismic or wind bracing?

With proper engineering. Use heavy-gauge profiles, seismic-rated fittings, and anchoring systems that meet ASCE 7 and IBC requirements. Bracing must be calculated for lateral loads, drift limits, and anchorage pullout strength. When strut supports limited energy systems, NEC 2026 requires compliant mechanical protection and grounding/bonding per Article 750.

12. What hardware uses strut as its infrastructure?

Strut serves as the backbone for mounting electrical boxes, conduit, threaded rod, cable tray, bridle rings, lighting fixtures, HVAC components, equipment racks, signage, and enclosures. It provides alignment, spacing, and modular support across ceiling grids, walls, and mechanical zones. In mixed‑voltage environments, NEC 2026 requires limited energy circuits to maintain proper separation and mechanical protection when sharing strut infrastructure with higher‑voltage systems.

13. How do you label and document strut assemblies?

Label by zone, load type, and system supported—e.g., “Zone 3: Cable Tray Support, 150 lb/ft.” Documentation should include profile, finish, fitting type, torque spec, and anchoring method. This supports inspection, maintenance, and MAC workflows. When strut supports limited energy systems, documentation should also reflect routing, separation, and mechanical protection requirements per NEC 2026.

14. What’s next for strut channel systems?

Expect tighter integration with BIM, pre-assembled kits, and smart labeling. Some systems now include QR-coded fittings, torque indicators, and modular seismic kits. The future is engineered, auditable, and field-ready. As limited energy systems expand under NEC 2026, expect more pre-engineered strut solutions designed specifically for compliant routing and protection of PoE and Class 2/3/4 circuits.

15. Does NEC 2026 change how strut is used for supporting limited energy systems?

NEC 2026 does not change strut channel itself, but it does update the requirements for any limited energy circuits supported by strut. This includes routing, mechanical protection, separation, grounding, bonding, and support spacing for PoE, communications cabling, and Class 2/3/4 systems. Installers must ensure that strut‑mounted limited energy systems follow Articles 720–723 for routing and protection, Article 742 for overvoltage protection, and Article 750 for grounding and bonding. The result is a more consistent and enforceable framework for mixed‑voltage environments.

Whether you're mounting conduit, bracing for seismic loads, or supporting multi-tier systems, strut channel delivers modular strength—but only when every fitting, fastener, and profile aligns with field logic and forensic precision.

The information provided in this FAQ is for general informational purposes only and is not intended to replace official codes, standards, or project specifications. Winnie Industries products must always be installed and used in accordance with our product instruction sheets or designated training. Products should never be applied beyond their intended purpose or in a manner that exceeds specified load ratings. Proper fastening is critical to system integrity and functionality, requiring secure attachment to structurally sound components capable of supporting imposed loads. All installations must comply with governing codes, regulations, and job site requirements. Always consult your Authority Having Jurisdiction (AHJ) for specific regulatory guidance.