When Cable Fights Back

Cable naturally retains the curved shape formed during packaging and transport, which, if not properly addressed before installation, can result in tension inconsistencies, recoil, or sagging—particularly in extended horizontal or overhead runs. These behaviors are amplified by cold environments, tight‑radius handling, and uneven support spacing, all of which make the cable harder to route and more likely to deform under load. A reliable deployment depends on fully relaxing the cable before routing, applying controlled tension during pulls, and maintaining consistent support throughout the run so the cable settles cleanly, protects its internal geometry, and delivers long‑term performance.

The following best practices outline practical steps installers use to manage cable memory and tension in a way that supports stable pathways and long‑term, code‑aligned performance.

1. Understand Cable Memory

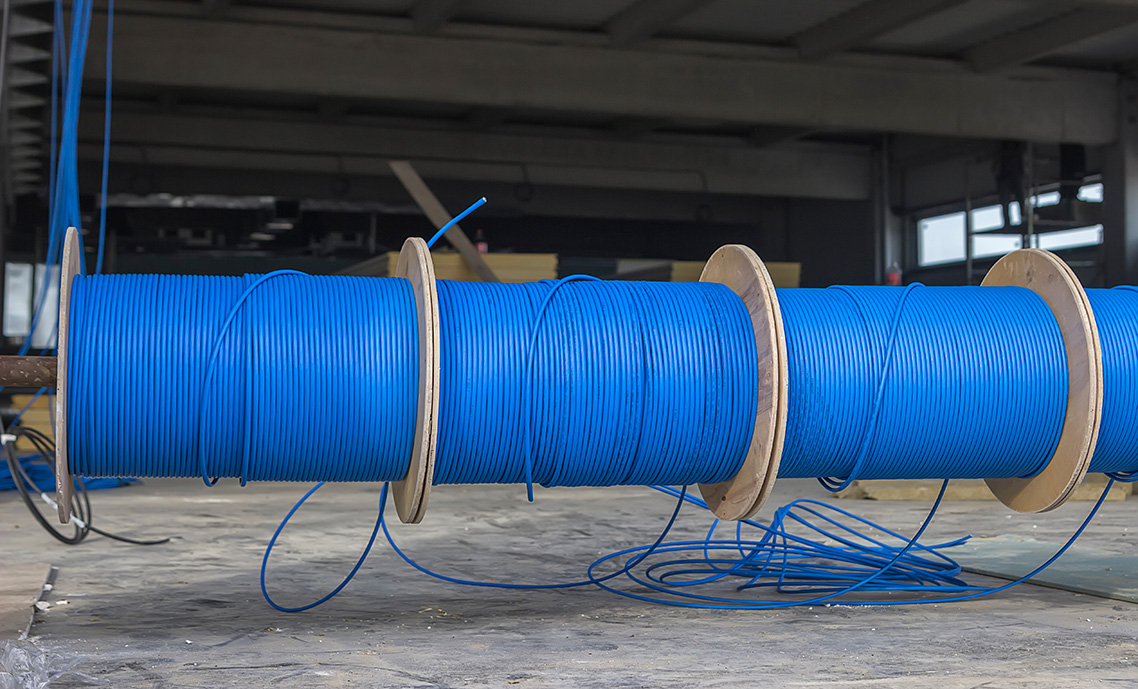

What It Is: Cable memory is the tendency of a cable to retain the shape it held on the reel or in the box, causing it to curl, twist, or resist laying flat during installation.

Why It Matters: Memory introduces mechanical stress into the pathway, making the cable harder to route and increasing the risk of deformation, sag, or performance issues.

Best Practice: Allow cable to relax before installation, straighten sections manually, and avoid forcing the cable into position while memory is still present.

2. Manage Tension and Sag

What It Is: Tension and sag refer to how the cable behaves under its own weight and during pulling, especially in long horizontal runs.

Why It Matters: Excess tension can deform the cable, while excessive sag can create uneven loading and stress points that worsen memory effects.

Best Practice: Maintain consistent support spacing and avoid over-pulling to keep tension balanced throughout the run.

3. Control Snapback and Recoil Hazards

What It Is: Snapback occurs when a cable under tension suddenly releases and recoils, often due to stored mechanical energy.

Why It Matters: Recoil can damage the cable, disrupt the pathway, or create safety hazards for installers.

Best Practice: Release tension gradually, avoid sharp directional changes, and monitor the cable for signs of stored energy during pulls.

4. Monitor Cable Twist

What It Is: Cable twist is the rotation or spiraling of the cable along its length, often caused by uneven pulling or memory.

Why It Matters: Twist increases mechanical stress, makes routing more difficult, and can lock in deformation if pulled through supports.

Best Practice: Stop the pull when twist appears, straighten the cable, and resume only when the cable lies naturally without rotation.

5. Adapt to Jacket Material and Environment

What It Is: Different jacket materials respond differently to temperature, handling, and bending, affecting how memory forms and releases.

Why It Matters: Cold environments stiffen jackets, increasing memory, while softer materials may deform more easily under stress.

Best Practice: Acclimate cable to the environment before pulling and adjust handling based on jacket type and temperature.

6. Respect Bend Radius During Relaxation

What It Is: Bend radius is the minimum curvature a cable can tolerate without damage or deformation.

Why It Matters: Tight bends lock in memory and create permanent deformation that affects performance and routing.

Best Practice: Use wide, smooth bends during setup and avoid forcing the cable into tight curves while it is still relaxing.

7. Maintain Proper Support Spacing

What It Is: Support spacing refers to the distance between j hooks, brackets, or other pathway supports.

Why It Matters: Wide spacing increases sag and exaggerates memory-related deformation, especially in long horizontal runs.

Best Practice: Keep support intervals tight and consistent to maintain a smooth, even pathway.

8. Follow Standards and Manufacturer Guidelines

What It Is: Industry standards and manufacturer recommendations define acceptable handling, pulling tension, and installation practices.

Why It Matters: Following these guidelines prevents damage, ensures compliance, and reduces the risk of memory-related issues.

Best Practice: Review and apply all relevant standards before installation and verify that handling practices align with manufacturer limits.

9. Identify Early Signs of Cable Memory

What It Is: Early signs include curling, stiffness, loops reforming after straightening, and cable that resists laying flat.

Why It Matters: Recognizing memory early prevents stress from being pulled into the pathway, reducing deformation and rework.

Best Practice: Pause before routing, straighten the cable manually, and allow it to relax until it settles naturally.

10. Address Cable Stiffness in Cold Conditions

What It Is: Cold temperatures stiffen cable jackets, making them more likely to retain tight curves and resist bending.

Why It Matters: Stiff cable exaggerates memory and increases the risk of kinks or deformation during installation.

Best Practice: Warm and acclimate cable before pulling and avoid routing until the jacket softens and moves freely.

11. Prevent Memory Through Proper Handling

What It Is: Handling practices such as tight-radius bends, sharp directional changes, or pulling from a stationary coil contribute to memory formation.

Why It Matters: Early handling errors lock in coil shape and create twist that becomes harder to correct once the run begins.

Best Practice: Use smooth, wide-radius handling during setup, unspool cable fully, and avoid tight bends at the start of the run.

12. Maintain Support Spacing to Control Memory Effects

What It Is: Memory-related deformation becomes more visible when support spacing is too wide or inconsistent.

Why It Matters: Uneven spacing increases sag and amplifies the mechanical stress caused by memory.

Best Practice: Keep spacing tight and uniform, avoid overloading supports, and maintain a smooth, even pathway.

13. Correct Twist Before It Becomes Permanent

What It Is: Twist that reappears after straightening or rotates the cable bundle during pulling indicates retained memory or uneven tension.

Why It Matters: If twist is pulled through supports, it becomes locked into the run and can affect performance.

Best Practice: Stop the pull, straighten the cable fully, and remove twist before continuing. Never pull through twist.

By addressing cable memory with disciplined handling and tension control, installers can prevent costly setbacks and lock in a stable, standards-compliant infrastructure from the very first pull.

This guide is intended for informational and reference purposes only. It does not supersede local codes, manufacturer specifications, or the judgment of the Authority Having Jurisdiction (AHJ). Installation practices must always be verified against current NEC, ANSI/TIA standards, and site-specific requirements. Winnie Industries products must be installed and used in accordance with official instruction sheets or designated training. Products should never be applied beyond their intended purpose or in a manner that exceeds specified load ratings. Proper fastening is critical to system integrity and functionality, requiring secure attachment to structurally sound components capable of supporting imposed loads. All installations must comply with governing codes, regulations, and job site requirements. Always consult your AHJ for specific regulatory guidance.