Board Discipline

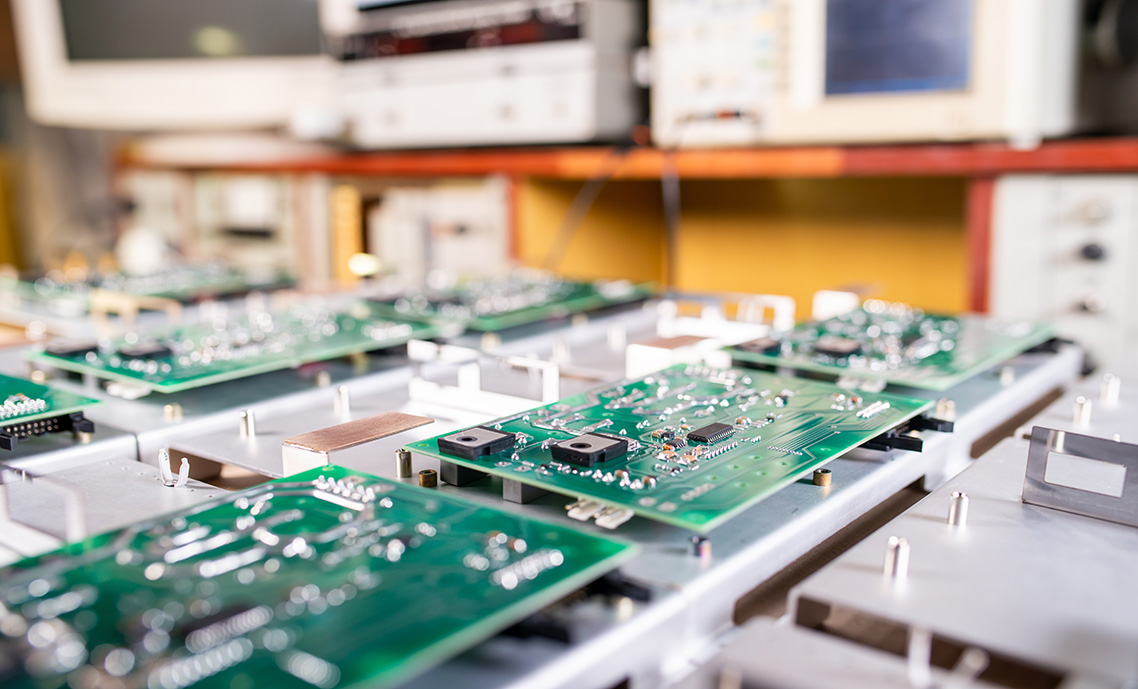

Printed circuit boards (PCBs) must be positioned, mounted, and integrated within enclosures to support system function, serviceability, and long-term reliability. Across industrial, security, fire alarm, data, embedded, and consumer systems, this includes board hierarchy, enclosure roles, mounting mechanisms, cable routing, grounding strategy, thermal control, and standards compliance.

To ensure reliable performance, safe installation, and standards-aligned servicing, each aspect of PCB integration must follow sequenced best practices across enclosure design, mounting, cabling, thermal control, and compliance.

1. Purpose and Deployment Context

Printed circuit boards (PCBs) are the structural and electrical foundation of electronic systems. Enclosures provide the physical infrastructure that protects, organizes, and interfaces these boards with the external environment.

These applications define where PCB mounting logic must be deployed with precision and standards alignment:

- Industrial control panels – housing logic boards, power distribution modules, and interface components for automation, manufacturing, and process control

- Security systems – intrusion detection, access control, CCTV, wireless communication, and alarm interface boards

- Fire alarm systems – smoke detection, annunciation, supervisory circuits, emergency communication, and notification logic

- Data systems – networking, edge computing, rack-mounted logic, and structured cabling integration

- Outdoor sensor housings – environmental monitoring, lighting control, traffic systems, and smart infrastructure nodes

- Embedded systems in HVAC, foodservice, and automation – integrating control logic, sensor inputs, power regulation, and multi-sensor detection boards for regulated life safety systems

- Consumer electronics and appliance control boards – supporting compact, serviceable enclosures with integrated user interfaces

All listed applications require validated mounting logic, serviceable access, and standards-compliant retention across environmental and regulatory constraints.

2. Board Placement and Hierarchy

Board placement defines how each PCB is positioned within the enclosure to support system function, cabling access, thermal behavior, and serviceability. Placement must be sequenced according to board role, enclosure geometry, and environmental constraints.

Use the following placement logic to ensure functional hierarchy, serviceability, and compliance:

- Primary logic boards should align with interface zones—cutouts, display windows, or access panels

- Power supply boards must be placed near the enclosure base or rear wall to support heat dissipation and dual power routing

- Interface boards (USB, Ethernet, RS-485, wireless) must mount adjacent to cutouts or panel connectors with strain relief

- Expansion modules or daughterboards should be stacked vertically or mounted on trays to preserve airflow and access

- RF or high-speed boards require isolation and shielding—mount near conductive gaskets or shielded compartments

- Sensor boards must be isolated from heat sources and mounted for unobstructed airflow and detection accuracy

- High-voltage boards require spacing and creepage clearance per IPC-2221—mount to prevent arcing and support grounding

All placements must support inspection, thermal behavior, and cable access—no provisional logic or obstructed zones allowed.

3. Mounting Methods

Mounting defines how each PCB is physically secured within the enclosure. Selection depends on enclosure geometry, vibration profile, serviceability requirements, and regulatory constraints.

Use the following mounting methods based on board role, enclosure type, and inspection tier:

- Screw + standoff mounting – threaded standoffs matched to bosses; machine screws secure without stressing substrate

- Magnetic standoff kits – modular retention without bosses; validate against board weight and vibration profile

- Snap-fit guides – slide-in retention for lightweight boards; confirm repeatable insertion and stress avoidance

- Adhesive mounting – foam tape or epoxy for non-critical boards; avoid heat zones and serviceable components

- Mounting plates – pre-assembled trays secured to enclosure; confirm rigidity and grounding strategy

- Component-based anchoring – use rated components as mounts; validate load and solder joint integrity

- DIN rail mounting – industrial carriers snapped into rails; confirm retention clips and grounding continuity

- Through-hole anchoring – press-fit terminals or pins into bosses; validate clearance and stress distribution

All mounting methods must support mechanical retention, electrical isolation (where required), and repeatable servicing.

4. Cabling and Routing Logic

Cabling defines how power and signal lines are routed between PCBs, connectors, and external interfaces. Routing must support electrical integrity, mechanical retention, serviceability, and compliance with enclosure constraints.

Apply the following routing logic to ensure signal integrity, serviceability, and standards compliance:

- Power cabling must run directly from supply board to load zones—short, strain-relieved, and compliant with NFPA 70 and UL 1424

- Signal cabling must be separated from power lines—use shielded or twisted-pair routing for sensitive signals

- Connector alignment must match enclosure cutouts—use grommets, glands, and validate mating clearance

- Service loops must support board removal or hinging—retain slack to prevent stress or airflow obstruction

- Grounding paths must be defined—use star grounding or ground planes; validate fault detection and loop integrity

- Cable management must support repeatable servicing—label cables and secure paths without obstructing airflow or diagnostics

All routing must be locked prior to inspection—no tensioned joints, obstructed connectors, or undocumented paths allowed.

5. Thermal and Environmental Control

Thermal and environmental control defines how heat, airflow, moisture, and contaminants are managed within the enclosure to protect PCB integrity and ensure long-term system reliability.

Apply the following controls to support survivability, inspection, and standards alignment:

- Heat-generating boards must mount near vents or conductive surfaces—support convection or forced airflow

- Vertical clearance between stacked boards must preserve airflow—validate against hardware height and routing zones

- Fan paths must remain unobstructed—preserve intake/exhaust zones and validate airflow direction

- Thermal pads and heat sinks must be secured—validate contact pressure, mounting torque, and passive dissipation

- Conformal coating and insulation must be applied in corrosive or vibration-prone zones—avoid connector interference

- IP rating and seal integrity must be validated—confirm gasket compression, fastener torque, and seam alignment

All thermal and environmental controls must be locked prior to inspection—no blocked airflow, unsealed zones, or unvalidated coatings allowed.

6. Standards, Inspection, and Field Compliance

This section defines how PCB-mounted systems are validated against electrical, mechanical, environmental, and regulatory standards. It supports inspection readiness, documentation integrity, and repeatable servicing.

Use the following compliance logic to ensure inspection-tier readiness and regulatory alignment:

- CAD documentation must label mounting points, connector zones, and enclosure interfaces—match geometry and support servicing

- Torque specifications must be defined and validated—prevent over-tightening or retention failure

- Color-coded hardware must support technician training—document logic and maintain consistency

- Vibration and thermal validation must confirm retention and signal integrity—simulate field conditions

- Standards compliance must be documented—UL, IPC, NEMA, NFPA, RoHS, and REACH must be traceable

- Tool-free access must be provided for serviceable zones—validate retention and sealing without compromising IP rating

- Environmental survivability must be scoped per deployment zone—validate coatings, seals, and shock resistance

All compliance elements must be locked before deployment—no undocumented specs, provisional mounts, or inspection failures allowed.

Mounting ends when every board is held with intent, every interface is resolved, and no tolerance remains unaccounted.

This guide is intended for informational and reference purposes only. It does not supersede local codes, manufacturer specifications, or the judgment of the Authority Having Jurisdiction (AHJ). Installation practices must always be verified against current NEC, ANSI/TIA standards, and site-specific requirements. Winnie Industries products must be installed and used in accordance with official instruction sheets or designated training. Products should never be applied beyond their intended purpose or in a manner that exceeds specified load ratings. Proper fastening is critical to system integrity and functionality, requiring secure attachment to structurally sound components capable of supporting imposed loads. All installations must comply with governing codes, regulations, and job site requirements. Always consult your AHJ for specific regulatory guidance.