Wire Today, Gone Tomorrow

Temporary cabling installations are short-term wiring deployments designed for rapid setup, full removability, and override-ready operation. Whether supporting power, datacom, or low-voltage systems, these installations must comply with NEC, OSHA, and AHJ standards—even when active for less than 30 days. Used across construction zones, entertainment venues, civic sites, and emergency response areas, temporary cabling must be labeled, traceable, and teardown-ready from day one.

The following questions break down the standards, mounting methods, teardown protocols, and inspection logic that govern temporary cabling across power, datacom, and low-voltage systems.

Scope & Application

1. What Is a Temporary Cabling Site?

A temporary cabling site is any location where cables are deployed for short-term use—typically under 90 days—and must support full teardown, reroute, override, and removal without damaging the structure or violating code. These sites require teardown-ready cable systems with inspection access, override logic, and full compliance with NEC, OSHA, and AHJ standards. Cabling must be labeled, mountable without permanent anchors, and removable without structural impact.

2. Where Are Temporary Cabling Sites Found?

- Airport Overflow Zones: Used for emergency response, mobile clinics, and temporary security systems.

- Churches and Religious Facilities: Used for polling, emergency shelter, outreach events, and temporary AV or low-voltage systems.

- Civic and Municipal Buildings: Used for temporary IT, AV, and power during public events or renovations.

- Concerts: Used for high-amperage power, AV, and lighting systems with rapid teardown and override logic.

- Construction Zones: Used for temporary power, lighting, and security systems.

- Emergency Response Centers: Used for rapid deployment of AV, datacom, and medical systems.

- Hotel Ballrooms and Conference Centers: Used for temporary AV, datacom, and low-voltage during events and conventions.

- Mobile Clinics and Trailers: Used for low-voltage and AV systems in healthcare and outreach settings.

- Outdoor Festivals and Civic Events: Used for AV, lighting, and power systems with teardown logic.

- Parking Structures and Lots: Used for outdoor festivals, drive-through clinics, and civic events.

- Polling Stations: Used for short-term AV, datacom, and low-voltage systems during elections.

- Retail Pop-Ups and Trade Show Booths: Used for AV, lighting, and datacom with teardown logic.

- School Gyms and Auditoriums: Used for temporary AV and control systems during assemblies, voting, and sporting events.

- Tent Structures and Temporary Shelters: Used in disaster relief, outreach, and mobile command centers.

- Theaters and Performance Venues: Used for AV, lighting, and control cabling during productions.

- University Field Houses and Lecture Halls: Used for voting, emergency response, overflow events, and sporting events requiring temporary AV or power systems.

- Warehouse Conversions: Used for pop-up clinics, voting centers, and temporary AV setups.

All temporary cabling at these sites must comply with NEC Article 590, OSHA 1910.305, and relevant ANSI/TIA standards for signal separation, mounting, and teardown labeling. AHJs may enforce additional local codes based on occupancy, voltage class, or fire/life safety systems.

Power Systems

1. What Cable Types Are Approved for Temporary Power?

Temporary power systems must use flexible, teardown-ready cables rated for the environment and load.

- SOOW and SJOOW: Used for outdoor and indoor temporary power. Rated for oil, water, and abrasion resistance.

- Type W: Used for high-amperage temporary feeders. Suitable for concerts, civic events, and industrial zones.

- MC (Metal-Clad): Used for temporary branch circuits in commercial interiors. Must be supported and labeled for teardown.

2. What Mounting Methods Are Approved for Temporary Power?

Power cables must be supported to prevent strain, trip hazards, and AHJ violations.

- Strut and Beam Clamps: Used for overhead routing. Must be load-rated and labeled.

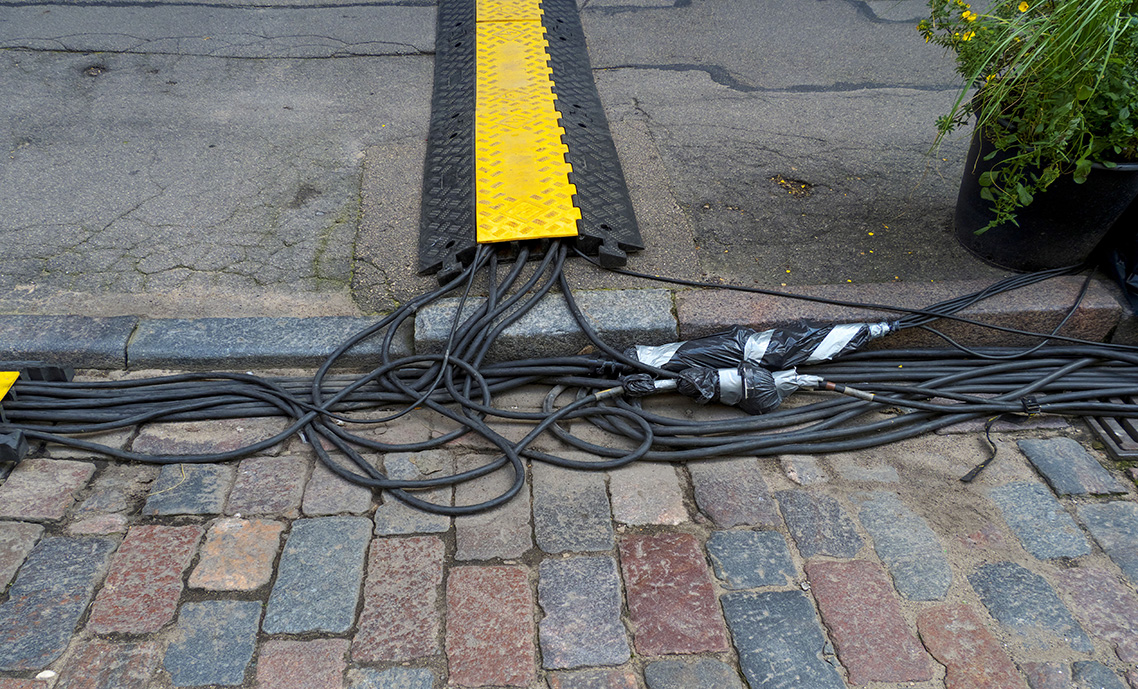

- Freestanding Ramps and Trays: Used to route cables across walkways and civic zones without structural mounting.

- Cable Hangers and Saddles: Used to support flexible cords along walls or ceilings. Must prevent sag and abrasion.

3. What Labeling and Teardown Protocols Apply to Temporary Power?

All power runs must be traceable, override-ready, and removable without damage or confusion.

- Source/Destination Labeling: Each run must be labeled at both ends for teardown and reroute.

- Override Tags: Used to flag alternate circuits or emergency reroutes.

- Service Loop Logic: Loops must be sized for retermination and labeled for reuse.

4. What Grounding and Surge Protection Is Required for Temporary Power?

Temporary power systems must meet NEC Article 250 grounding rules and include surge protection for sensitive gear.

- Bonding Methods: Use listed connectors per NEC 250.8. Bond all metallic enclosures and raceways.

- Ground Rods: Required for standalone panels. Must be tested for resistance and labeled.

- Surge Protection: Install panel-level surge devices and rack-mounted protectors for AV and control gear.

Datacom Systems

1. What Cable Types Are Used in Temporary Datacom Setups?

Temporary datacom systems support AV, IT, and control networks using teardown-ready cable types.

- Cat 5e/6/6A: Used for Ethernet, AV control, and POS systems.

- Coaxial: Used for broadcast, RF, and surveillance feeds.

- HDMI: Used for temporary video distribution in theaters and polling stations.

- Fiber: Used for high-bandwidth AV and long-distance control systems.

2. What Mounting Methods Are Approved for Datacom?

Datacom cables must be mounted using teardown-ready supports that preserve signal integrity and allow for full removal without damage.

- J Hooks and Bridle Rings: Mounted using strut, beam clamps, threaded rod, or pre-punched channel. Must be labeled and separated by signal type.

- Magnetic Cable Managers: Includes magnetic J hooks, plastic saddles, and magnetic bridle rings—valid only on steel surfaces.

- Adhesive Anchors: Used on drywall, glass, or non-metal surfaces—must support teardown without residue.

- Freestanding Trays and Ramps: Used in civic zones to route cables without structural mounting.

- Zip Ties and Hook & Loop Wraps: Approved only in low-tension zones. Must not constrict bundles or interfere with teardown.

3. What Labeling and Override Logic Is Required for Datacom?

All datacom runs must support emergency reroutes and teardown mapping.

- Dual-End Labeling: Source and destination must be clearly marked for teardown.

- Override Tags: Used to flag reroutes, emergency bypasses, or alternate signal paths.

- Service Loop Logic: Loops must be sized for retermination and labeled for reuse.

- Continuity and Labeling Verification: All runs must be tested for continuity and matched to teardown labels before deployment.

4. What Are the Risks of Cable Tray Misuse in Datacom Zones?

Improper use of cable trays can lead to overheating, signal degradation, and AHJ violations.

- Overheating: Stacked bundles restrict airflow and increase fire risk.

- Arc-Flash Risk: Mixing voltage classes in shared trays violates NEC separation rules.

- Label Loss: Bundled trays obscure teardown labels and override tags.

- AHJ Violations: Improper tray use can trigger inspection failures and forced teardown.

Low-Voltage Systems

1. What Cable Types Are Used in Temporary Low-Voltage Installations?

Low-voltage systems include security, access control, intercom, and sensor networks. Temporary runs must use teardown-ready cable types.

- 22/2 and 22/4: Used for door contacts, motion sensors, and basic intercom systems.

- 18/2 and 18/4: Used for power-limited fire alarm and access control devices.

- Shielded Twisted Pair: Used for audio, control, and interference-sensitive runs.

- Composite Bundles: Used for multi-function devices requiring power and signal in one sheath.

- FPL/FPLR/FPLP: Used for temporary fire alarm systems. Must meet plenum or riser ratings and be routed per NFPA 72 survivability requirements.

2. What Mounting Methods Are Approved for Low-Voltage Cabling?

Low-voltage cables must be mounted using supports that allow full removal, reroute, and override without damaging the structure or signal integrity.

- J Hooks and Bridle Rings: Mounted with strut, beam clamps, or threaded rod. Must be labeled and teardown-ready.

- Magnetic Cable Managers/product-category/magnetic-products/: Valid on steel surfaces. Includes magnetic saddles and magnetic J hooks.

- Adhesive Anchors: Used on drywall, glass, or masonry. Must support clean removal.

- Cable Ramps and Freestanding Trays: Used in civic zones, polling stations, and temporary venues.

- Hook & Loop Wraps and Zip Ties: Approved only in low-tension zones. Must not constrict or deform cable bundles.

3. What Labeling and Teardown Protocols Apply to Low-Voltage Systems?

All low-voltage runs must be traceable, override-ready, and removable without damage or confusion.

- Source/Destination Labeling: Each run must be labeled at both ends for teardown and reroute.

- Override Tags: Used to flag alternate signal paths or emergency reroutes.

- Service Loop Logic: Loops must be sized for retermination and labeled for reuse.

- Device ID Mapping: Cables must be mapped to temporary device IDs for teardown tracking.

4. Can Low-Voltage Cables Share Trays with Datacom or Power?

No—low-voltage cables must be separated by signal type and voltage class. Shared trays violate NEC and AHJ separation rules.

- Signal Separation: Low-voltage must be routed separately from datacom and power to prevent interference.

- Tray Labeling: Each tray must be labeled by signal type and teardown zone.

- AHJ Enforcement: Shared trays may trigger inspection failures and forced reroutes.

AV Systems

1. What Cable Types Are Used in Temporary AV Installations?

AV systems in concerts, theaters, and civic venues rely on teardown-ready cables designed for audio, video, and control signal integrity.

- XLR: Used for balanced audio—microphones, mixers, and stage feeds.

- DMX512: Used for lighting control. Must meet ANSI E1.27-1 shielding and impedance specs.

- TRS and TS: Used for instruments and line-level audio. TRS supports stereo or balanced; TS is mono/unbalanced.

- Speakon: Used for high-power speaker connections. Locking connectors preferred for teardown safety.

- HDMI and SDI: Used for video distribution. SDI preferred for long-distance, high-definition feeds.

- Optical (TOSLINK): Used for digital audio transmission with immunity to electrical interference.

- RS-232: Used for serial control of projectors, switchers, and legacy AV gear. Requires shielded twisted pair or multi-conductor cable with labeled DB9 connectors.

2. What Mounting Methods Are Approved for AV Cabling?

AV cables must be mounted using teardown-ready supports that preserve signal quality and allow rapid removal after events.

- Truss Clamps and Batten Hooks: Used for overhead routing in theaters and concert venues. Must be load-rated and labeled.

- Freestanding Ramps and Trays: Used to route cables across walkways and civic zones without structural mounting.

- Magnetic Cable Managers: Valid on steel surfaces. Includes magnetic saddles and magnetic J hooks.

- Hook & Loop Wraps and Gaffer Tape: Used for temporary bundling and floor routing. Must not constrict or damage cable jackets.

- J Hooks and Bridle Rings: Used with strut or beam clamps for overhead routing. Must be teardown-ready and labeled.

3. What Labeling and Teardown Protocols Apply to AV Systems?

All AV runs must support teardown, reroute, and override logic for rapid post-event recovery.

- Source/Destination Labeling: Each run must be labeled at both ends for teardown and reroute.

- Override Tags: Used to flag alternate signal paths or emergency reroutes.

- Service Loop Logic: Loops must be sized for retermination and labeled for reuse.

- Control Channel Mapping: DMX, RS-232, and AV control cables must be mapped to device IDs and teardown zones.

4. What Standards Apply to AV Control and Lighting Cables?

AV control cables must meet ANSI and TIA standards for shielding, separation, and teardown labeling.

- ANSI E1.27-1: Defines DMX512-A cable specs for lighting control systems.

- TIA-568 and TIA-862: Apply to structured cabling and building automation systems used in AV control.

- Shielding and Impedance: Cables must match system specs and avoid signal bleed or crosstalk.

- Separation from Power: Control cables must be routed away from power to prevent interference.

- Labeling for Teardown: All control cables must be labeled for reroute, override, and retermination.

5. Can AV Cables Be Suspended from Truss or Battens?

Yes—AV cables may be suspended from truss, battens, or pipe grid using load-rated clamps, hooks, or mousing ties. All suspended runs must be labeled, teardown-ready, and approved by the AHJ or venue authority.

- Load-Rated Hardware: Use only clamps, carabiners, or cable hangers rated for the cable weight and environment.

- Strain Relief: Cables must be supported at intervals to prevent sag, tension, or jacket damage.

- Teardown Access: All suspended runs must be reachable for safe removal without ladders or lifts where possible.

- AHJ and Venue Approval: Suspended cable paths must be reviewed by the AHJ or venue safety officer prior to deployment.

Temporary cabling may be short-term, but its execution demands full accountability—every run must be mounted, labeled, and ready to tear down without compromise.

The information provided in this FAQ is for general informational purposes only and is not intended to replace official codes, standards, or project specifications. Winnie Industries products must always be installed and used in accordance with our product instruction sheets or designated training. Products should never be applied beyond their intended purpose or in a manner that exceeds specified load ratings. Proper fastening is critical to system integrity and functionality, requiring secure attachment to structurally sound components capable of supporting imposed loads. All installations must comply with governing codes, regulations, and job site requirements. Always consult your Authority Having Jurisdiction (AHJ) for specific regulatory guidance.